centrifugal compressor|centrifugal compressor models and efficiency : distributors To weigh the advantages between centrifugal compressors it is important to compare 8 parameters classic to turbomachinery. Specifically, pressure rise (p), flow (Q), angular speed (N), power (P), density (ρ), diameter (D), viscosity (μ) and elasticity (e). This . See more To increase the longevity of your autoclave, it’s best to clean them on a daily, weekly, monthly, and annual basis. But don’t feel overwhelmed. Each autoclave maintenance tip has its own recommended cleaning frequency.

{plog:ftitle_list}

2012 • Lagarde Autoclaves patented a new multifunctional handling system. 2006 • Development and patent of the first worldwide regulation system for retort based on industrial PC named .Lagarde Autoclaves is the international leader of autoclave. Steam and Air technology inventor, devoted to the thermal process treatment.

types of centrifugal compressor

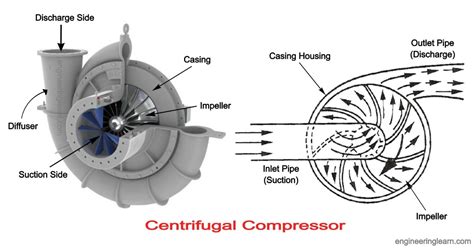

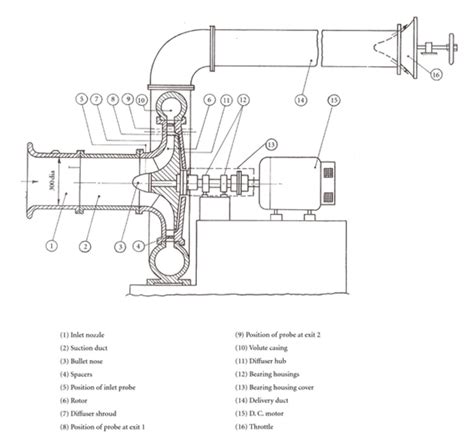

Centrifugal compressors, sometimes called impeller compressors or radial compressors, are a sub-class of dynamic axisymmetric work-absorbing turbomachinery. They achieve pressure rise by adding energy to the continuous flow of fluid through the rotor/impeller. The equation in the next . See moreA simple centrifugal compressor stage has four components (listed in order of throughflow): inlet, impeller/rotor, diffuser, and collector. Figure . See more

schematic diagram of centrifugal compressor

Centrifugal compressors are similar in many ways to other turbomachinery and are compared and contrasted as follows:Similarities to axial . See more

StandardsAs turbomachinery became more common, standards have been created to guide manufacturers to assure end-users that their products meet minimum safety and performance requirements. Associations . See more

To weigh the advantages between centrifugal compressors it is important to compare 8 parameters classic to turbomachinery. Specifically, pressure rise (p), flow (Q), angular speed (N), power (P), density (ρ), diameter (D), viscosity (μ) and elasticity (e). This . See more

Over the past 100 years, applied scientists including Stodola (1903, 1927–1945), Pfleiderer (1952), Hawthorne (1964), Shepherd (1956), Lakshminarayana (1996), and Japikse (many texts including citations), have educated young engineers in the fundamentals . See more

In the case where flow passes through a straight pipe to enter a centrifugal compressor, the flow is axial, uniform, and has no vorticity, i.e. swirling motion. As the flow passes through . See moreWhile illustrating a gas turbine's Brayton cycle, Figure 5.1 includes example plots of pressure-specific volume and temperature-entropy. These types of plots are fundamental to understanding centrifugal compressor performance at one operating point. The two plots . See more

Learn how a centrifugal compressor compresses a fluid with the help of the impeller's radial acceleration and the diffuser's pressure conversion. Explore the c.

how does centrifugal compressor work

About Sundyne. Sundyne is the world leader in delivering low-flow, high-head, integrally geared centrifugal pumps and compressors, sealless magnetic drive pumps and diaphragm gas compressors. A centrifugal compressor is a type of dynamic compressor, or turbo compressor, with a radial design.Unlike displacement compressors that work at a constant flow, dynamic compressors work at a constant pressure and the performance is affected by external conditions such as changes in inlet temperatures. How Does a Centrifugal Compressor Work? Air is .How a Centrifugal Compressor Works. Acceleration: The rotational motion of the impeller imparts kinetic energy to the gas molecules, causing them to accelerate radially outward. Turning Speed into Pressure: When the gas moves through the diffuser, which is a part that widens out, its speed is transformed into pressure. The diffuser takes fast-moving, low-pressure air from the impeller .Centrifugal Compressors Designed to deliver Reliability and High-Performance Roots® Centrifugal Compressors offer a diverse range of sizes, providing a wide spectrum of performance and controllability.

Centrifugal compressors are described along with all the required information, definition, components, working, applications, pros, and cons.Back to Basics be distributed around the circumference of the compressor, CEP compressor. = ); CC () So, how does a centrifugal gas compressor work, and what oil and gas applications are they used for? Check out this video to find out! Gas compressors can be.

How Does a Centrifugal Compressor Work?FS-Elliott is a leading manufacturer of oil-free, centrifugal compressors with sales, service, and manufacturing locat.

DENAIR air compressor factory is a world's leading manufacturer for air compressors with Germany Technology. A full range of air compressors are available for all industries.

Centrifugal compressors are dynamic, which means that compression is performed by converting kinetic energy into static energy. The characteristic of a centrifugal compressor is that the head is determined by the volume flow through the unit. A centrifugal compressor with an axial inlet (a typical full-wheel gearbox) uses a hose of the appropriate length to.Hitachi has supplied over 1300 centrifugal compressors around the globe, since the first one was completed in 1911. Centrifugal compressors meet various needs, and their main applications are in oil refineries, chemical plants, fertilizer plants, natural gas plants, steel plants, etc.Throughout the last decades, centrifugal compressor research and development have been revolutionized. Computational fluid dynamics have provided a better understanding of the flow and physical phenomena, and the design of new cen trifugal compressor components has been transformed from an "art" into a "sci ence".Have you ever wondered how air gets compressed by a centrifugal compressor? Here’s how!For more information on Japan’s leading centrifugal compressor manufac.

What Is a Centrifugal Air Compressor? Centrifugal Air Compressors are a form of dynamic compressor, that efficiently convert the kinetic energy of a rotating compressor fan into compressed air utilizing a series of stages to compress and cool the air as it continuously flows through the compressor. Most modern passenger and military aircraft are powered by gas turbine engines, which are also called jet engines. There are several different types of jet engines, but all jet engines have some partsin common. All jet engines have a compressor to increase the pressure of the incoming air before it enters the burner. Compressor performance has a large influence .

Centrifugal compressors, also known as dynamic compressors, efficiently converts the energy utilizing a series of stages to compress and cool the air as it continuously flows through the unit.A centrifugal compressor imparts kinetic energy into the airstream by increasing the velocity of the air using a rotating element and then converts this kinetic energy into potential energy in the .Centrifugal Compressor Centrifugal Compressors. A centrifugal compressor is a radial flow rotodynamic fluid machine that uses mostly air as the working fluid and utilizes the mechanical energy imparted to the machine from outside to . Centrifugal air compressor basics Compressor capacity should be stated at plant conditions and centrifugal air compressors are best suited to applications where demand is relatively constant.Other articles where centrifugal compressor is discussed: compressor: Centrifugal compressors increase the kinetic energy of the gas with a high-speed impeller and then convert this energy into increased pressure in a divergent outlet passage called the diffuser. Centrifugal compressors are particularly suited for compressing large volumes of gas to moderate pressures.

assess for meniscus tear with which test

Centrifugal compressors use centrifugal force to compress gas by feeding it into a wheel, or impeller, with radial vanes that accelerate the gas away from the wheel center.

Centrifugal Compressor is a machine in which a particular gas or vapor is compressed by a radial acceleration by an impeller with the help of a surrounding case.Centrifugal Compressors. Jason Wilkes, . George Talabisco, in Compression Machinery for Oil and Gas, 2019. Interaction With Reciprocating Compressors and Aerodynamic Stability. Strong pressure pulsations into the suction or discharge of a centrifugal compressor can move its operating point into operational instability regions such as surge, rotating stall, or choke.

Centrifugal compressors increase the kinetic energy of the gas with a high-speed impeller and then convert this energy into increased pressure in a divergent outlet passage called the diffuser. Centrifugal compressors are particularly suited for compressing large volumes of gas to moderate pressures. In axial compressors the gas flows parallel to the axis of rotation of the rotor, which .

centrifugal compressor vs axial compressor

Compressed air is often called the “fourth utility” when applied to industrial operations. However, unlike water, gas and electricity the consumer is also typically the producer.Oil-Free, Risk Free The first to be certified ISO 8573-1:2001 Class 0, our oil-free centrifugal compressors offer efficient, economical and reliable solutions for delivering compressed air. These high-performing, versatile compressors provide 100% oil-free air in all operating conditions.

centrifugal compressor pdf

The different types of centrifugal compressors include:. Single-stage Centrifugal Compressor – it has a single impeller and is used for low-pressure applications.; Multi-stage Centrifugal Compressor – it has two or more impellers and is used for high-pressure applications.; Radial Centrifugal Compressor – it has an impeller that expels air perpendicular to its axis.2 3 IMPRINT CONTENTS Editor-in-Chief: Patrick Kessler – Cologne, Germany Marketing Communications Atlas Copco Gas and Process Division Concept, Design, Text:

centrifugal compressor parts and functions

$3,909.95

centrifugal compressor|centrifugal compressor models and efficiency